- Home

- Non-standard Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

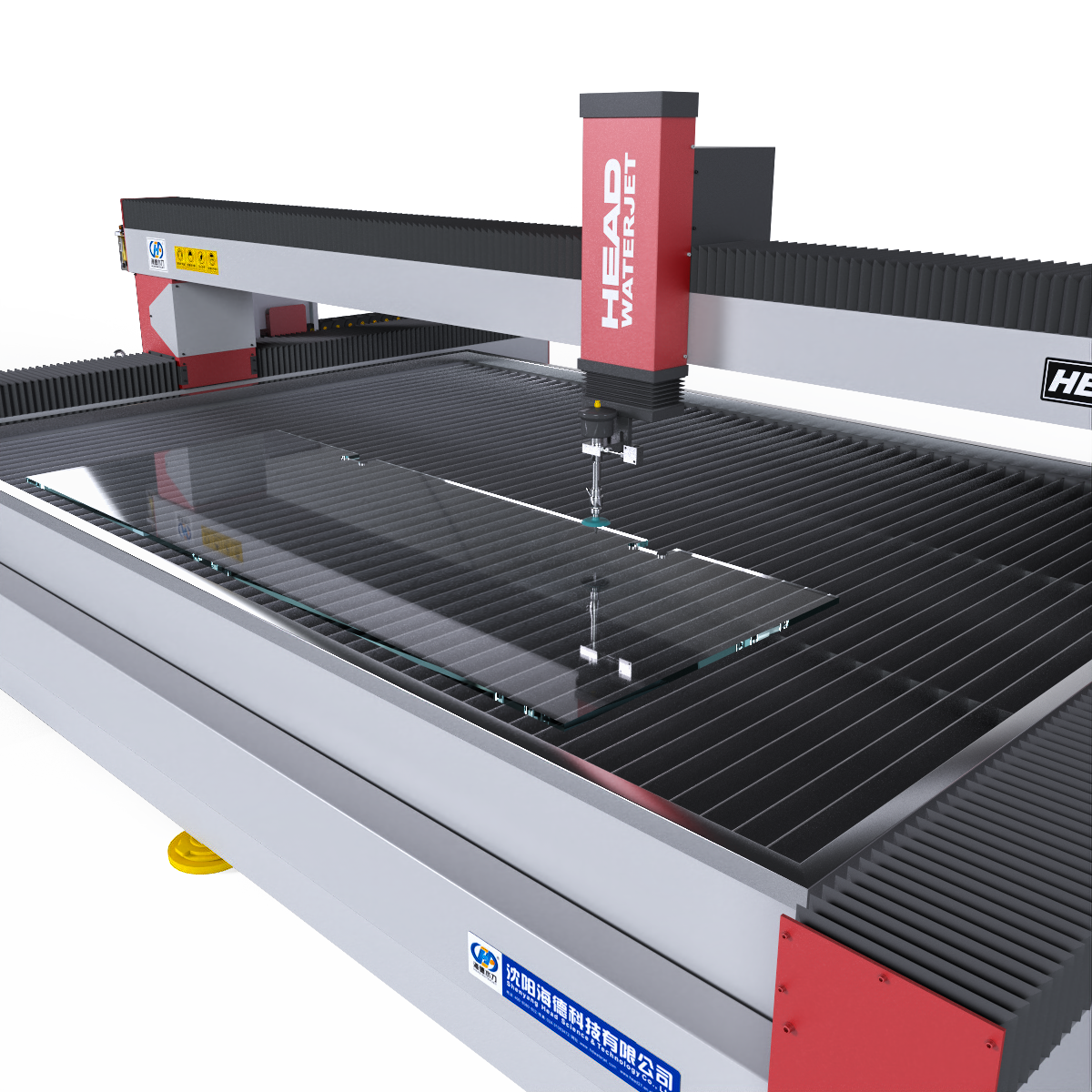

HEAD3020BA-3A

HEAD

| Availability: | |

|---|---|

Cutting Video

Product Description

We are excited to offer you our top-notch waterjet glass cutting services. Cutting glass has never been easier with our fast and efficient waterjet technology.

You can cut a variety of glass products without changing tools, making it a convenient option for all your glass cutting needs.Whether you need architectural glasswork or simply want to cut a mirror, our waterjet glass cutting services are the perfect solution.

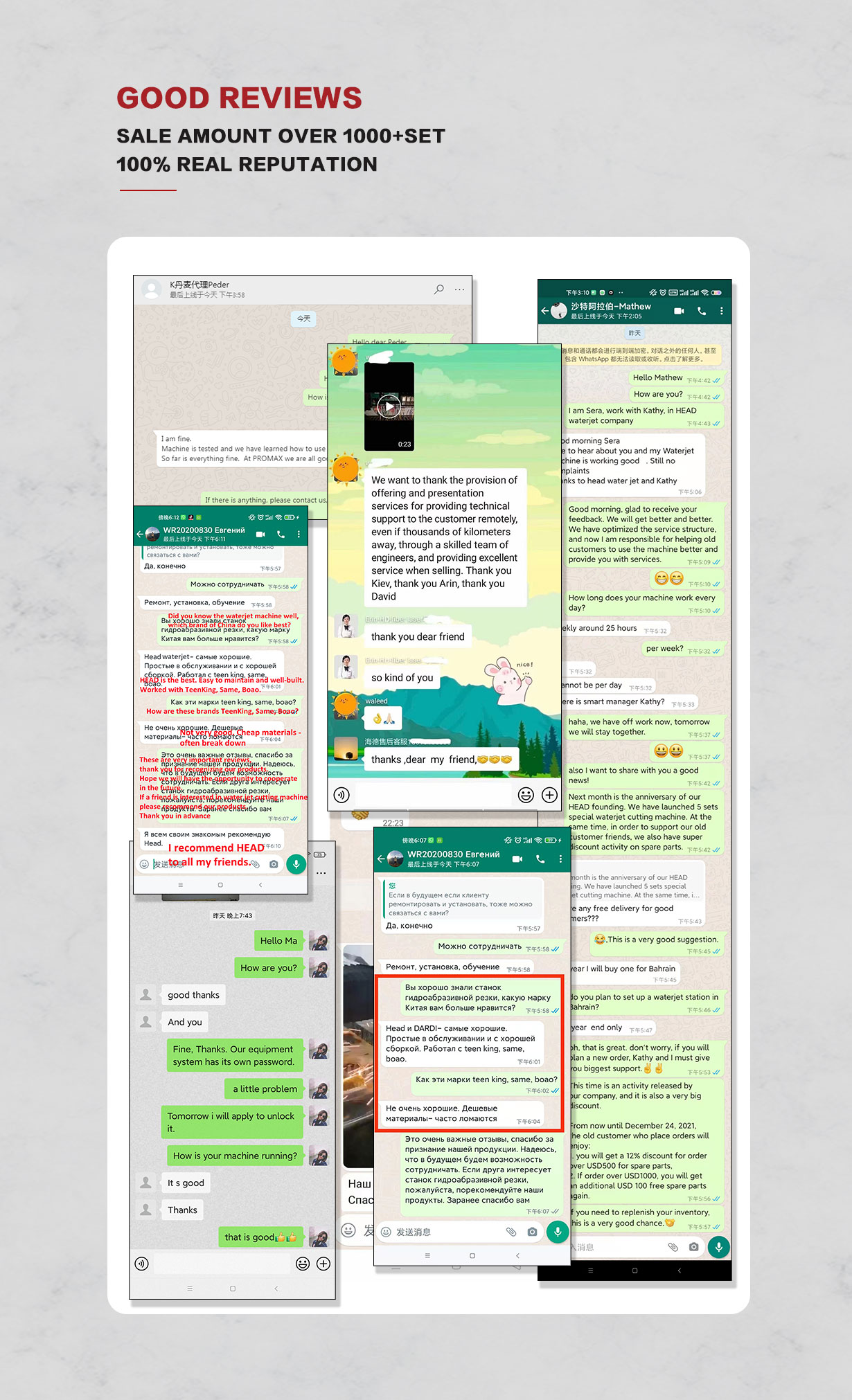

Welcome to HEAD WaterJet! We are proud to serve customers worldwide with our exceptional waterjet services. Thank you for choosing HEAD WaterJet!

Waterjet has become the industry standard process for cutting glass due to its time and cost effectiveness.

Capable of cutting precise internal cuts, they are suitable for cutting a variety of glass products including

Glass Tabletops,

Shower Door,

Insulated Glass,

Stair Treads,

Mirror,

Automotive-Glass,

Appliance Glass.

Why is a waterjet the best tool for cutting glass?

Waterjet cutting has become very popular in many industries due to its exceptional versatility. HEAD Waterjet sells high-quality machines that can cut anything from delicate lead glass to thick, sturdy glass products.

Waterjet can cut any shape, no matter how complex, faster than most other glass cutting processes. Waterjet glass cutting machines provide excellent edge quality without blurring and rarely require secondary finishing processes. It is time-saving and economical.

Yes, even the strongest ballistic and bulletproof glass can be cut using a waterjet.

Therefore, water jets are frequently used in the aerospace, rail transportation, and petrochemical equipment industries.

Cutting Glass Sample

Free sample trial cutting service!

>>>Try to Read This -------Our Service

1. Maintenance free of charge for 12 months .

2. We will provide the consumable parts at an agency price.

3. 24 hours online service, free technical support.

4. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

5. We have manual instruction and Videos for software Installation, operation and machine's using and maintenance; We will send professional technician to customers' factory, provide them two-weeks training, including working principle of machine, Auto CAD drawing, common problems and solution, etc.

Try to Read This -------FAQ

Q1: Does This Machine Pass CE Certificate?

A2: Yes, this machine passed European CE certificate and meet Safety Standard.

Q2: How much of cutting thickness?

A2: Marble is 0-120mm; granite is 0-110mm; tiles are 0-40mm; glass and mosaic is 0-80mm; steel, stainless steel, copper is 0-60mm; aluminum is 0-80mm; plastic, acrylic, foam is 0-200mm. With our double-pressures system, it can cut 0-160mm steel sheet, 0-200mm stones. It is good for customers cut thicker materials.

Q3: How fast of speed?

A3: Speed depends on cutomers' materials and cutting requirement, and customers can adjust speed parameters.

Why Choose Waterjet

The advantages of waterjet are the reason promoting the development of waterjet. Although there are a lot of advantages, they almost can come down to "versatility". By using a waterjet, we can efficiently and cost-effectively create a wide range of parts by using widely different materials.

Keep safety

Although anything can be cut through, waterjet is still very safe. It is because we don't need to put any body parts under the waterjet cutting head while it is on, obviously. If there is a leak in a high-pressure water system will tend pressure rapidly drop to safe level. Water itself is safe and non-explosive and the garnet abrasive is also inert and non-toxic. So using waterjet to cut material is very safety.

Environmentally friendly

As long as we are not machining a material that is hazardous, the spent abrasive and waste material become suitable for land fill. The garnet abrasive is inert and can be disposed of with our other trash.If we are machining lots of lead or other hazardous materials, we will still need to dispose of our waste appropriately, and recycle the water. Keep in mind, however, that very little metal is actually removed in the cutting process. This keeps the environmental impact relatively low, even if we do machine the occasional hazardous material.In most areas, excess water is simply drained to the sewer. In some areas, water treatment may be necessary prior to draining to sewer. In a few areas, a "closed loop" system that recycles the water may be required.

Our Package Advantage:

1. Our Wooden Case is after fumigation treatment. Needn't timber inspection,saving shipping time.

2. All the spare parts of the machine were bovered by some soft materials,mainly using Pearl Wool.

Avoiding all damages that could happen in the delivery process.Then we'll covered plastic wrap out it tightly, make sure intact of the covered soft materials,also avoiding Waterproof and rust proof.

3. The outmost is Wooden Case With Fixed Formwork.

4. The bottom of the wooden case has firm iron jack,convenient to Handling and transport.

Before delivery, we would do the test about 20-30 working hours for machine, and use standard packing to each configuration. We choose famous export company and transport company, making shipment more convenient and safer.

Accessories

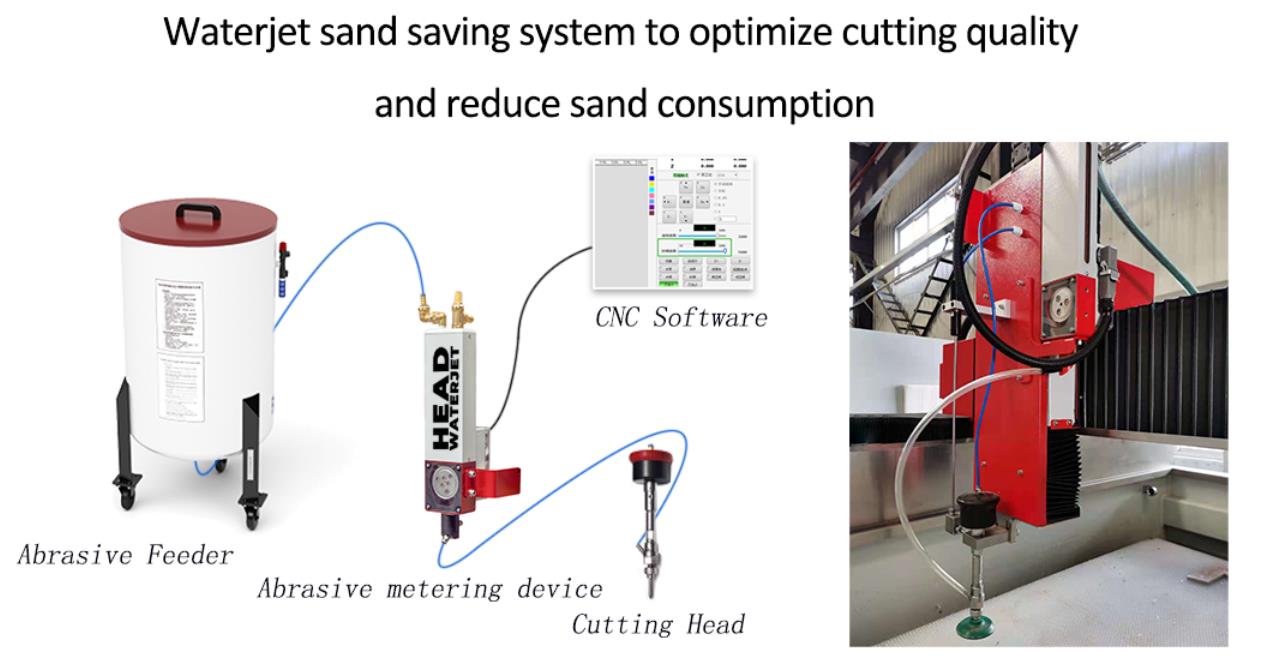

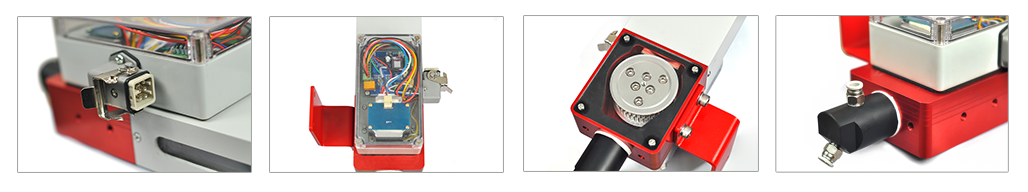

In order to better optimize the consumption of waterjet sand (abrasive) in the water cutting process, we have optimized and upgraded on the basis of the original standard sand control system, and developed a new generation of electronic sand control system. The sand flow rate is controlled by the software to ensure the consistency of the cutting surface. It is especially suitable for high-precision processing. It can better record the sand supply parameters when cutting specific materials, optimize the water jet sand consumption, and reduce the water jet usage cost.

After the water cutting machine has been used for a long time, waste abrasive will accumulate in the water tank . When it reaches a certain level, we will inevitably carry out sand removal operations. In traditional abrasive removal, we must shut down, drain water, and manually dig sand to remove sand. The abrasive removal is completed. The water tank must be filled with water again. cumbersome process not only consumes time and labor, but also delays the normal operation of water jet cutter, waterjet abrasive removal system operation can be completed efficiently, conveniently and environmentally. Once the product came out, it has been well received by the industry. After the design staff's upgrade and innovation, three generations of HEAD automatic sand removal system have been launched for users to choose.

| Clean up the deposited waste sand at any time without affecting the normal production. |

| Simple equipment operation, all operations can be mastered in 10 minutes |

| HEAD automatic abrasive removal system with reasonable structure, simple maintenance and no wearing parts. |

| HEAD automatic abrasive removal system is equipped with special pump unit to keep the sand content in the platform below 10% and the clear water quality |

| The abrasive removal system has a large capacity, which can meet the general sand cleaning requirements by running twice a day. |

| The comprehensive use cost of equipment will create 50,000 USD per year |