- Home

- Non-standard Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

The machines offer universal cutting solutions for the precise machining of complex geometries with cutting angle correction and bevel cutting. The models cover a wide range of cutting areas and can be customized with additional equipment options.The pressure intensifier pump core components is produced by the well-known manufacturer Accustream in USA, which is one of the world's leading manufacturers of high-pressure technology.

The company HEAD waterjet has been manufacturing high-quality waterjet cutting systems since 2009 and is thus one of the first system providers on the china market for waterjet cutting machines!

This special field developed from our business field, which has been active since 2009, the automation and overhaul of machine tools and the construction of special purpose machines. Our customers worldwide benefit from this wealth of experience!

Installation & Debugging

Clients arrange technician getting training in our factory or we send technician to client's side until the

operator masters the basic technique of using the machine.

The seller will provide technical guide online via e-mail, telephone, WeChat, WhatsApp or Teamview etc.

ControNest CAM-Software

Easy to operate CAM software

ControNest was specially developed for cutting machines

The software includes an embedded CAM module, with which CAD drawings, nesting and material databases can be imported, which means no expensive additional CAM software is required.

Company profile video

Features

1. Integrated design

2. Harness optimization, increase shielding, improve anti-interference ability

3. The opening size is large, the maintenance window is large, and the maintenance convenience is increased.

4. Safety linkage, the equipment stops immediately when the maintenance opening is opened.

5. The rotation range is plus or minus 120 degrees

6. Integrated screen, key layout, ergonomic

7. Intensifier pump: Omron/Siemens PLC, Siemens motor, Japan Yuken directional valve, USA intensifier to ensure pump high quality.

8. Cutting table: Panasonic servo motor. Hiwin linear guide, ABBA ball screw, auto lubrication system, Z axis double linear(Most are single linear guide, it is easy to deform for a long time using) and Y axis welding metal structure cutting table(Most is just welding metal) to improve stabled performance and accuracy. X beam is one-time extrusion forming aluminium alloy,light and high rigid.

9. CNC controller; Software from Weihong the best and professional brand, schneider electric part etc.

10. For abrasive feeder, top and bottom air supply to ensure sand supply stability to ensure cutting quality.

11. We supply soften water system for you to improve intensifier pump and spare parts using life.

| SPECIFICATIONS FOR WATER JET CUTTING MACHINE | |||

| Cutting table | 3000*2000mm | ||

| Max. pressure | 420MPA | ||

| Max. flow rate | 3.7L / min | ||

| Electrical source voltage | 3 phases 220/380/400/415/480V-50/60HZ-3PH | ||

| Max. diameter of nozzle / orifice | 1.02mm / 0.33mm | ||

| Z axis travel | 150mm | ||

| Max. delivery capacity of oil pump | 106L / min | ||

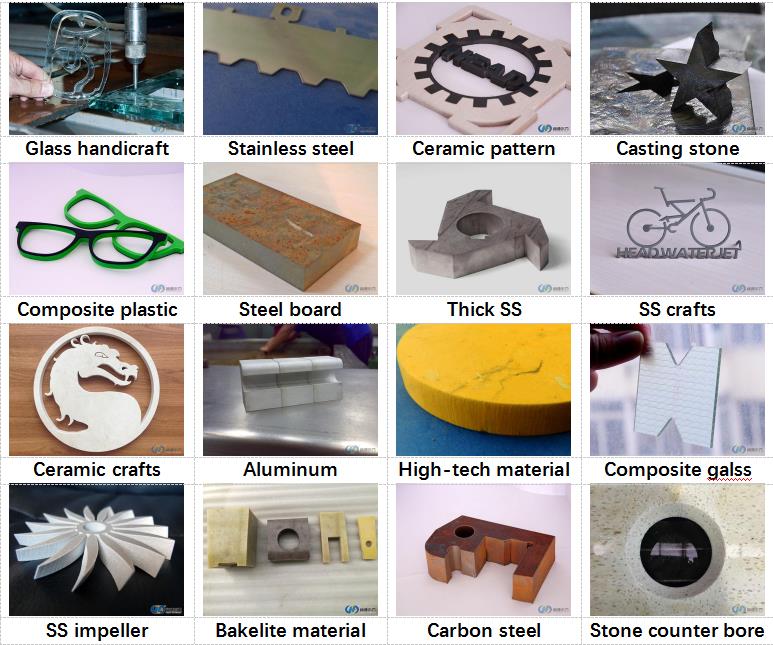

| Applicable cutting material | Sincered stone, Marble, Ceramic Mild steel, stainless steel, aluminium, brass, copper | ||

| Warranty | 1 Year(not include the consumable parts) | ||

| Cooling model | Air cooling/Water/Oil cooling | ||

The complete set of waterjet equipment includes:HEAD3020BA CNC cutting platform, CNC system, ultra-high voltage generator,

cutting head system(Optional 5AB/5AC 5axis cutting head)HEAD auto abrasive feeder system.

Cutting sample