- Home

- Non-standard Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HEAD4020BA-5AC

HEAD

HS code: 84565000

Average price of machine 63000 usd

| Availability: | |

|---|---|

Product Details

Equipment composition

Stone cutting machine includes: HEAD4020BA CNC cutting platform, CNC system, flip frame, laser height measurement, high-pressure pump, remote control, soft water system, cutting head system (optional 5AB/5AC five-axis cutting head)

1. High Pressure pump: OMRON/Siemens PLC, Siemens motor, Japan Yuken reversing valve, U.S. booster pump, to ensure the high quality of the pump.

2. Cutting table: Panasonic servo motor, Hiwin linear guide, ABBA ball screw, automatic lubrication system, Z-axis double linear (most of them are single linear guide, easy to be deformed by long-term use), Y-axis welded metal+concrete structure cutting table (most of them are only welded metal), to improve the stability and precision. x-beam is made of one-time extruded aluminum alloy with low weight and high rigidity.

3. CNC controller; professional brand Weihong software, Schneider electrical components, etc.

4. Abrasive supply, upper and lower air supply, to ensure stable supply of abrasive to ensure cutting quality.

5. We provide you with soft water system to improve the service life of pump and spare parts.

Technical Parameters

Model | HEAD4020BA |

Working area | 4000*2000mm |

Equipment size | 5300*3400*2200mm |

Equipment weight | 2280kg (single platform without water tank) |

AC five-axis travel | 3600*1600*150 |

Power | 220/380/400/415/480V-50/60HZ-3PH |

Repeat positioning accuracy | ±0.05mm |

Platform load-bearing capacity | 500kg/㎡ |

Cooling model | Air cooling/Water/Oil cooling |

Cutting Video/Sample

HEAD Waterjet cutting offers numerous advantages when cutting metals, making it an ideal choice for precise, efficient, and safe machining. Unlike traditional cutting methods, waterjet cutting operates without heat, preserving the material's integrity and preventing thermal distortion. It delivers clean, accurate edges with minimal burrs, reducing the need for secondary finishing. The technology is versatile, capable of cutting a wide range of metals, including tough alloys like titanium and stainless steel, with no tool wear involved, ensuring consistent performance over time. Additionally, waterjet cutting is environmentally friendly, producing no fumes or hazardous waste. It is also highly efficient, cutting complex shapes and intricate designs without the need for extra steps or costly tooling, and it maintains a high level of safety by eliminating sparks and hot surfaces, protecting both operators and equipment..

Option Introduction

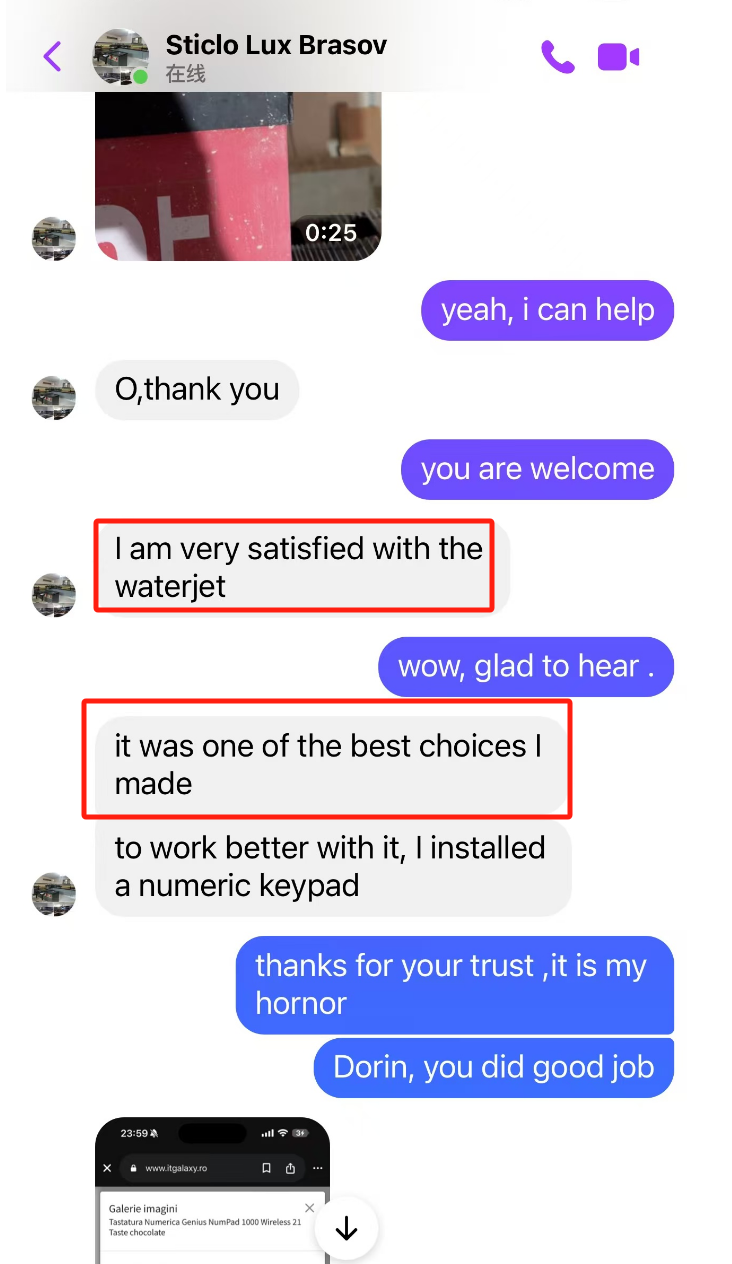

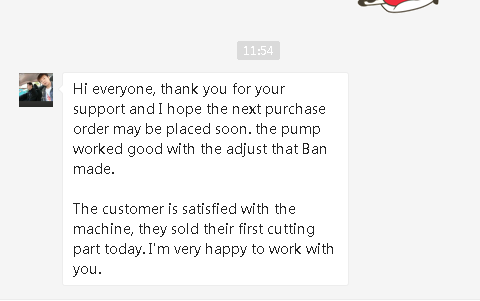

Customer Reviews