- Home

- Non-standard Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HEAD1520BB

HEAD

hs code:84565000

| Availability: | |

|---|---|

Product Description

Keeping track of latest market development we are actively engaged in offering CNC Water Jet Cutting Machine. Widely used for cutting soft & hard materials, the offered jet cutting machine is good demand in the market for its high performance. In order to assure the quality, the complete range of jet cutting machine is checked on numerous parameters before the final delivery at the customer’s end. The offered jet cutting machine is provided with different specifications at affordable price.Our experience in the water jet industry has allowed us to include the small details that will save you time and money in the long run. All our machines are built and sold with the following features

50 HP High 420 MPa pressure for smooth finish cutting at high speed.

Main heart of Supercharger, "Intensifier" is "Made in USA".

User friendly & minimum maintenance cutting head design with USA make "Water Switch Seal Kit" & other parts.

All parts of machine are processed on Highly accurate YASKAWA servo motor (made in Japan). Which gives you trouble free operation & long life of parts.

Separate body between cutting table and load-bearing platform prevents interfering cutting accuracy from long-term stress variation to load-bearing platform.

X beam of cutting table applies the one-off extrusion forming aluminum alloy, light weight, strong steel, not deformed, is the most advanced technology .

Cancelling dustproof cloth on X, Y, Z axis and hiding Y axis towline greatly improve the machine life and save the maintenance cost.

Motor and ball screw are directly connected by flexible coupling. It can absorb vibration energy reversible and with higher drive accuracy compared with other torsional rigid coupling.

Using high-quality international brand ball screw, linear guide transmission structure to ensure the moving speed and accuracy of the cutting head.

The cutting head is with casting structure and concrete structure. The metal parts have been specially processed to eliminate traces of deformation and to maintain long-term mechanical precision.

| Max.cutting range(mm) | 1500*2000mm |

| Running speed | 6000mm/min |

| Travel of Z axis | 150mm |

| Repeat positioning accuracy | ±0.025mm/m |

| Control accuracy | ±0.01mm |

| Cutting accuracy | ±0.1mm |

| SPECIFICATIONS FOR WATER JET CUTTING MACHINE | |||

| Max. pressure | 380-420MPA | ||

| Max. flow rate | 3.7L / min | ||

| Electrical source voltage | 3 phases 220/380 Voltage, 50/60Hz, 37KW, 50HP | ||

| Max. diameter of nozzle / orifice | 1.02mm / 0.33mm | ||

| Max. delivery capacity of oil pump | 106L / min | ||

| Drive type | Yaskawa Servo Drive | ||

| Max cutting heads | 1-10 cutting heads (1 for standard machine) | ||

Cooling device helps high pressure pump work better in hot places

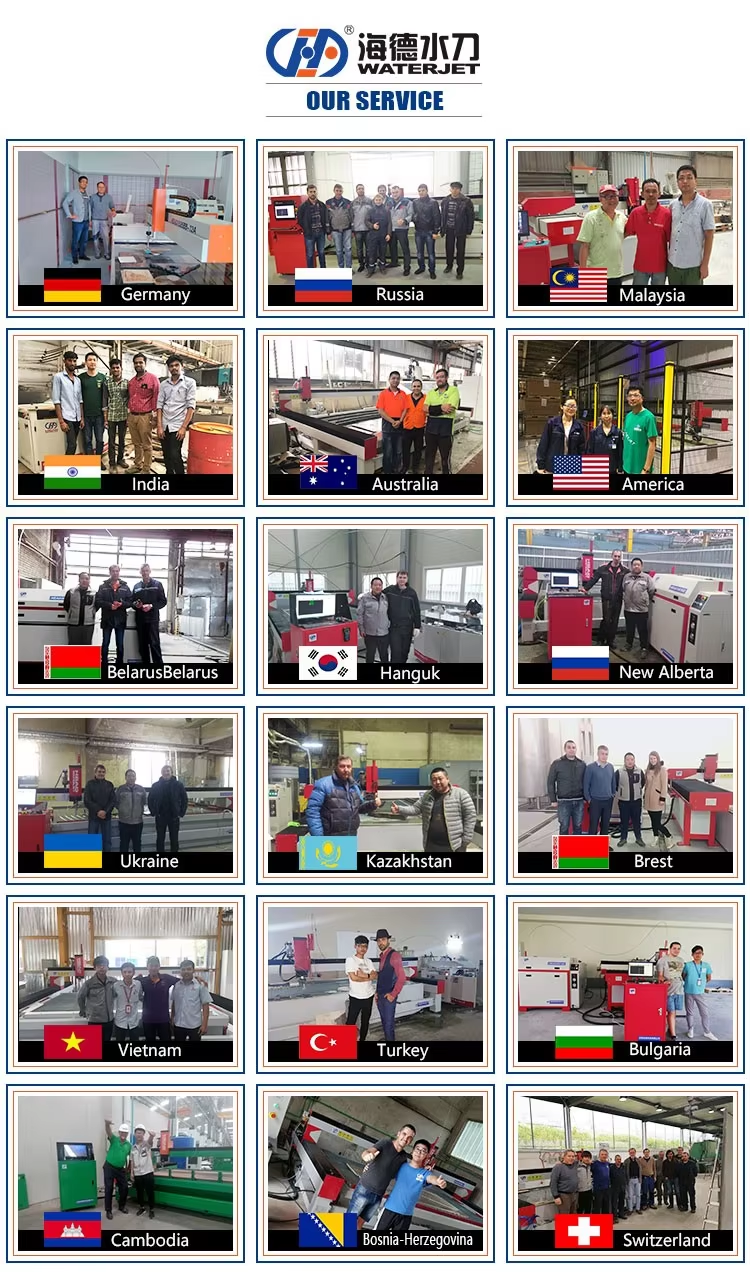

Our Service

Sufficient spare parts supply

Quality Inspection for HEAD Waterjet Machines

At HEAD Waterjet, quality is at the core of everything we do. Our commitment to delivering high-performance cutting machines means that every system undergoes rigorous quality control and testing before it reaches you.

After-Sales Service Excellence for Waterjet Cutting Machines

At HEAD Waterjet, we understand that reliable after-sales service is as crucial as the performance of our cutting machines. We are committed to offering unparalleled support to ensure your operations run smoothly and efficiently.

Key Benefits of Our After-Sales Service:

24/7 Support: Our dedicated service team is available around the clock, ensuring quick resolutions to any issues you may encounter, minimizing downtime and maximizing productivity.

Comprehensive Training: We provide detailed training to your team on machine operation, maintenance, and troubleshooting, empowering you to get the most out of your equipment.

Cost-Effective Maintenance: We offer affordable, transparent pricing for all after-sales services, helping you control operational costs without compromising on quality.

Global Reach: With an extensive network of service centers and technicians, we guarantee fast and efficient support no matter where you are.

Genuine Parts and Upgrades: We use only genuine parts to ensure the long-term reliability and performance of your equipment. Additionally, we offer periodic upgrades to keep your machine running at peak efficiency.

Choose HEAD Waterjet for reliable performance and peace of mind—our after-sales service is designed to keep your operations running seamlessly.