- Home

- Non-standard Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 35 Author: Site Editor Publish Time: 2021-07-30 Origin: Site

Customer case: large-scale high-end customized waterjet assists thick metal processing

Company name: A large European machinery manufacturing company

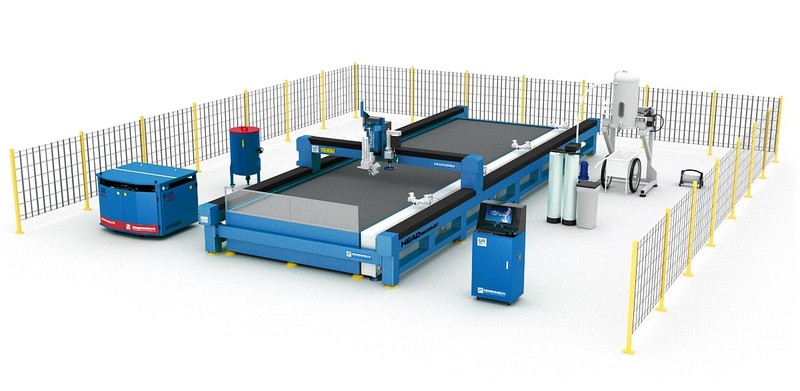

Water jet model: HEAD2580BA-5AC/HEAD42037Z

Russia is a superpower of heavy industry. The main economic industry is metal processing, which occupies a major part of its processing industry. Russia is an important overseas market of HEAD Science & Technology Ltd,. Co, and the most of customers comes from metal processing industry, and HEAD waterjet has provided cutting solutions for them many times. At present, the trend of metal processing in Russia market is mostly metal with thickness over 200mm and larger size, and the requirements for precision and standards are quite high so as to ensure the yield of cutting materials, which once again puts a test on our company's R&D ability and capability of production and assembly .

The difficulties of this cutting solution are as follows

1. Inspection and calibration of precision on this so large platform

2. Mutual cooperation and overall control of functional diversity

3. Safety protection for operators and elimination of cutting noise

4. The arrangement of large workpieces on the cutting platform.

5. Guarantee of accuracy of on-site installation and debugging

To meet requirements and tackle the technical difficulties, the R&D team customized a super-large water jet cutting machine (HEAD2580BA-5AC/HEAD42037Z ) specially for thick metal cutting through continuous research and discussion with experts from Chinese Academy of Sciences.

The cutting travel of the equipment can reach 2500×8000×300mm, and the magnetic grating ruler is equipped to ensure the full closed-loop control of the machine tool, and the cutter head can realize angle cutting; The display screen automatically rises during the cutting to prevent splashing of water and sand.

The machine was equipped with a drill bit, used for drilling composite materials to eliminate the phenomenon of layering. Patrol positioning function help automatically find the cutting edge and avoid collision. Emergency stop line can better protect the cutting head and ensure the safe operation of the equipment; The water tank is submerged type, which can realize underwater cutting with lower cutting noise.

AC5-axis cutting head+drill+edge patrol positioning+anti-collision

The AC 5-axis cutting head can perform 3D cutting and can process complex workpieces such as impellers. The drill bit first punches holes when processing composite materials to avoid material stratification when drilling directly with a water jet. The edge positioning and anti-collision system can ensure that the cutting head will not collide when processing large-format uneven workpieces.

High-pressure pump supports stepless pressure changing from 50 to 410 and touch screen can realize pressure regulation. The screen displays working pressure, working time and alarm information etc.

High-pressure pump supports stepless pressure changing from 50 to 410 and touch screen can realize pressure regulation. The screen displays working pressure, working time and alarm information etc.

Adopted ECS software system which supports Russian language. Equipped with air conditioning and Russian software.

The abrasive feeding system (capacity of 1000kg) was equipped with sensors for low-grade abrasives. The feeding of abrasive into the cutting head shall be carried out in a mini hopper with a capacity of at least 1kg located on the gantry.

The engineers made of good use of laser interferometer and laser tracker to ensure the assembly accuracy of this large-size platform, which help ensure the positioning accuracy and repeated positioning accuracy reach ±0.025mm. This solution passed the third-party authoritative certification test such as TUV.

The customer who ordered this equipment said that they originally thought only suppliers in Europe and US could complete such high-tech project, but Chinese suppliers like HEAD waterjet has proved our technical strength. HEAD waterjet will as always repay you with our best service, you can trust on us since we use the technical process of aircraft manufacturing to produce water jet cutting machine.

Leica AT960 Absolute Laser Tracker