- Home

- Non-standard Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HEAD-BLSCX-LD

HEAD

HS code: 84565000

| Availability: | |

|---|---|

Product Description

Tailored for Your Production Line—Efficient, Precise, Worry-Free Production

HEAD Waterjet presents the Glass Door Slot Cutting Automation Solution, specifically designed for shower screen production lines. By leveraging advanced technology, automated processes, and customized services, we help you improve production efficiency, reduce costs, and ensure product quality. Whether for large-scale production or small-batch customization, we provide the perfect cutting solution for your needs.

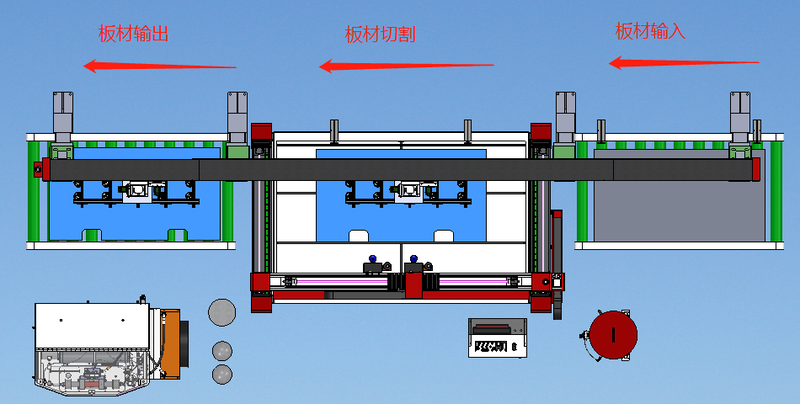

Fully Automated Loading & Unloading System

Say goodbye to manual handling with our fully automated loading and unloading system, which efficiently manages the in-feed and out-feed of glass doors. This ensures smooth production flow, increases operational efficiency, and reduces human error. The optimized process brings greater intelligence to your production line.

Intelligent Automatic Positioning Technology

Each glass door is precisely positioned using intelligent automatic alignment, ensuring that every cut is accurate and consistent. This eliminates the errors that can arise from manual positioning, ensuring that each glass door meets design specifications.

Dual Cutting Heads for Synchronized Operation

Our dual cutting head system works in sync, significantly boosting production efficiency. Compared to traditional single-head cutting solutions, the dual-head system doubles the cutting speed, making it ideal for high-efficiency, large-volume production and helping shorten delivery times.

Customizable Solution

We offer flexible, tailor-made services based on your specific production needs. Whether for different specifications or process requirements of glass doors, we provide a solution that fits your production line perfectly, ensuring that your needs are always met, even as market demands evolve.

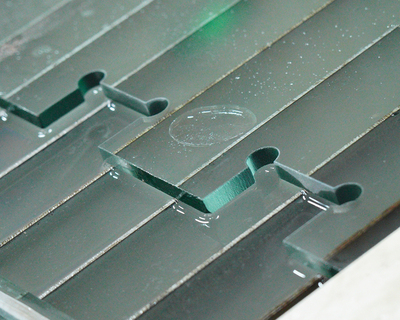

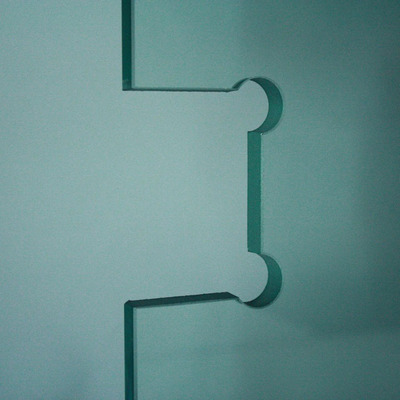

High-Precision Cutting Technology

Using high-precision waterjet cutting technology, our solution avoids the thermal effects typically associated with traditional cutting methods, ensuring no deformation or cracking of glass. Every glass door is cut with top-notch accuracy, achieving industry-leading standards in both dimensional precision and cut quality.

Cutting Samples

This solution is ideal for the glass door slot cutting process in shower screen production lines, especially in production environments where cutting precision and efficiency are crucial. Whether you're running large-scale production or small-batch customized orders, this solution delivers high-efficiency and precise cutting to meet diverse customer needs.

Increased Production Efficiency: Fully automated loading & unloading, intelligent positioning, and synchronized dual cutting heads greatly boost efficiency, reducing production times.

Reduced Production Costs: Automation minimizes labor costs and optimizes the entire production process, reducing error rates.

Assured Cutting Precision & Quality: High-precision waterjet cutting ensures each glass door is cut accurately, enhancing consistency and quality.

Flexible Customization: Tailored services to meet diverse production needs, adapting to different specifications and production scales.

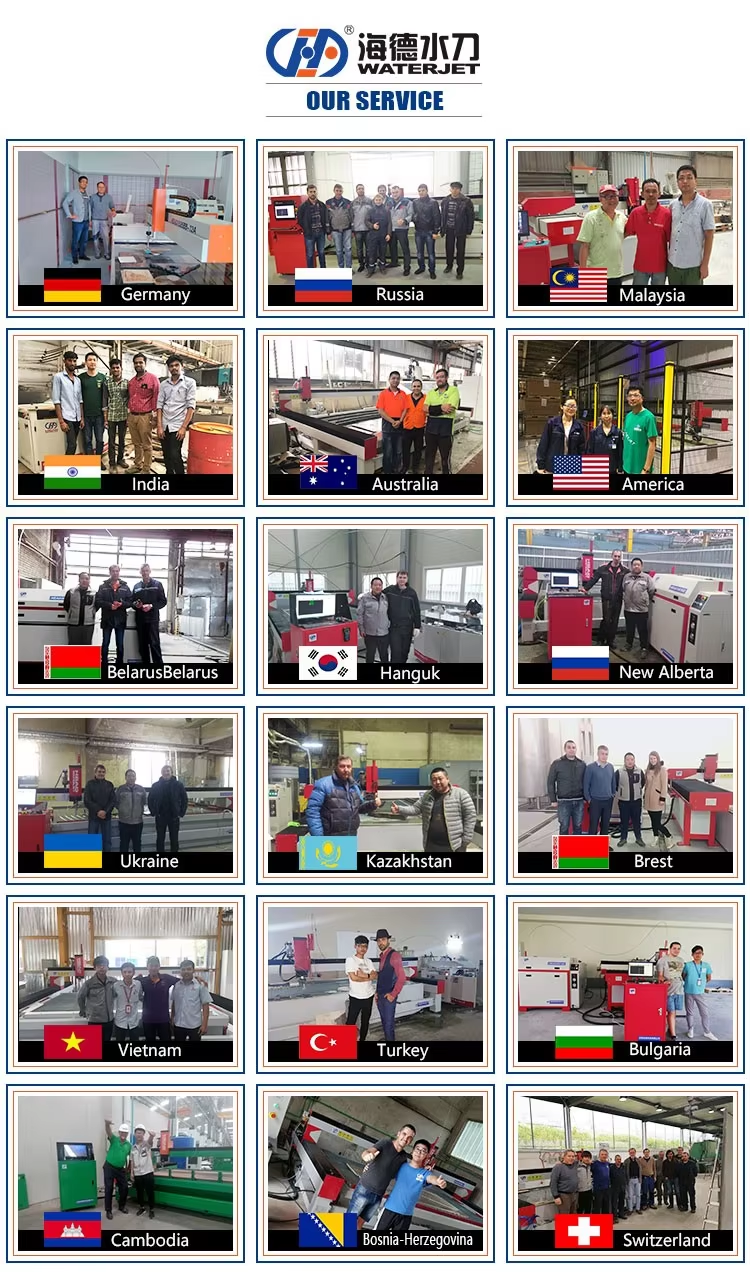

Our Service

After-Sales Service Excellence for Waterjet Cutting Machines

At HEAD Waterjet, we understand that reliable after-sales service is as crucial as the performance of our cutting machines. We are committed to offering unparalleled support to ensure your operations run smoothly and efficiently.

Key Benefits of Our After-Sales Service:

24/7 Support: Our dedicated service team is available around the clock, ensuring quick resolutions to any issues you may encounter, minimizing downtime and maximizing productivity.

Comprehensive Training: We provide detailed training to your team on machine operation, maintenance, and troubleshooting, empowering you to get the most out of your equipment.

Cost-Effective Maintenance: We offer affordable, transparent pricing for all after-sales services, helping you control operational costs without compromising on quality.

Global Reach: With an extensive network of service centers and technicians, we guarantee fast and efficient support no matter where you are.

Genuine Parts and Upgrades: We use only genuine parts to ensure the long-term reliability and performance of your equipment. Additionally, we offer periodic upgrades to keep your machine running at peak efficiency.

Choose HEAD Waterjet for reliable performance and peace of mind—our after-sales service is designed to keep your operations running seamlessly.