- Home

- Non-standard Cases

- HEAD Products

- HOT

- Service&Support

- Success Cases

- Applications

- About Us

- Contact Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HEAD1010BA

HEAD

hs code:84565000

| Availability: | |

|---|---|

Product Description

Customer Needs

The client, an Australian steel group operating in China, required a solution for tensile testing sample preparation that could:

Non-Destructive Testing:

Accurately cut steel pipes while preserving their original structural integrity and chemical composition.

Precise Cutting:

Perform high-precision cuts that eliminate the need for secondary processing.

Enhanced Efficiency:

Reduce the time and labor involved in preparing tensile testing samples.

Noise Reduction:

Implement submerged cutting technology to minimize noise during operation.

Versatility:

Accommodate different pipe sizes and shapes with an adaptable system.

Based on these requirements, HEAD Technology designed a tailored solution using the HEAD1010BA-BG Water jet Cutter:

Laser Height Measurement

Automatically adjusts the cutting height for precise operations, scanning the material and generating a cutting trajectory with pinpoint accuracy.

Custom V-Shaped Pipe Supports

Provides stable centering for pipes of various diameters, with quick-change adapters for different models.

Pneumatic Clamping System

Adjustable clamping with one fixed end and one pneumatic-driven movable end ensures secure and efficient handling.

Cold-State Submerged Cutting

Eliminates thermal damage, preserves material properties, and significantly reduces operational noise.

Integrated Design

Compact, single-structure system for easy installation, mobility, and after-sales support.

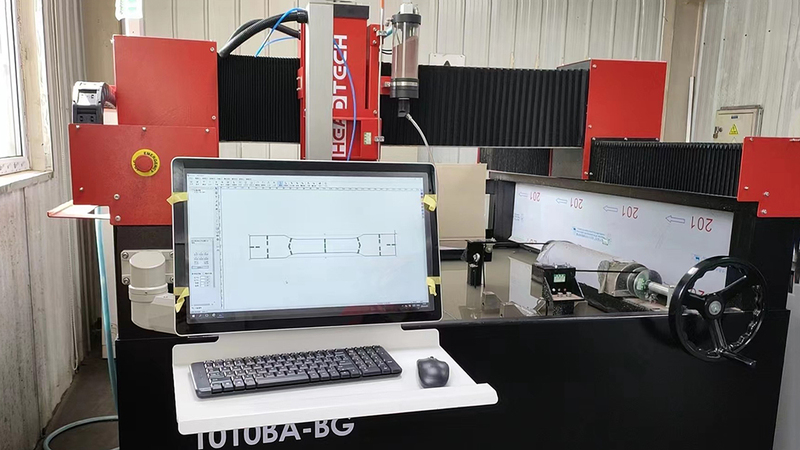

Real shots of finished equipment used by customers

| Technical Parameters | |

| Max.cutting range(mm) | 1000*1000mm |

| Running speed | 6000mm/min |

| Travel of Z axis | 150mm |

| Repeat positioning accuracy | ±0.025mm/m |

| Control accuracy | ±0.01mm |

| Cutting accuracy | ±0.1mm |

Steel Pipe Sample Preparation

Cut round, square, and channel steel pipes for tensile testing.

Material Quality Control

Perfect for non-destructive material analysis and integrity assurance.

Industrial R&D

A reliable solution for laboratories and steel processing industries.

Finished sample cut by HEAD tensile testing special waterjet cutting machine

Pipes to be sampled by customers

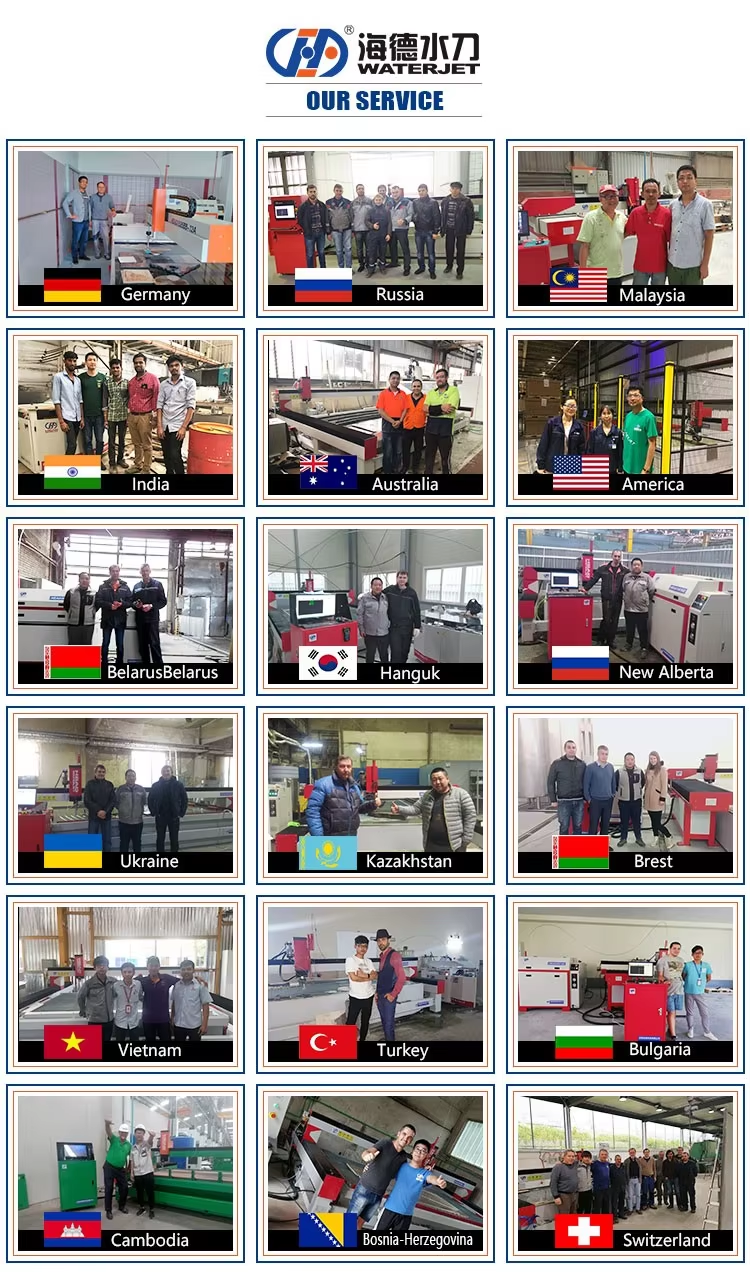

Our Service

After-Sales Service Excellence for Waterjet Cutting Machines

At HEAD Waterjet, we understand that reliable after-sales service is as crucial as the performance of our cutting machines. We are committed to offering unparalleled support to ensure your operations run smoothly and efficiently.

Key Benefits of Our After-Sales Service:

24/7 Support: Our dedicated service team is available around the clock, ensuring quick resolutions to any issues you may encounter, minimizing downtime and maximizing productivity.

Comprehensive Training: We provide detailed training to your team on machine operation, maintenance, and troubleshooting, empowering you to get the most out of your equipment.

Cost-Effective Maintenance: We offer affordable, transparent pricing for all after-sales services, helping you control operational costs without compromising on quality.

Global Reach: With an extensive network of service centers and technicians, we guarantee fast and efficient support no matter where you are.

Genuine Parts and Upgrades: We use only genuine parts to ensure the long-term reliability and performance of your equipment. Additionally, we offer periodic upgrades to keep your machine running at peak efficiency.

Choose HEAD Waterjet for reliable performance and peace of mind—our after-sales service is designed to keep your operations running seamlessly.

Quality Inspection for HEAD Waterjet Machines

At HEAD Waterjet, quality is at the core of everything we do. Our commitment to delivering high-performance cutting machines means that every system undergoes rigorous quality control and testing before it reaches you.

Customer Reviews