- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 6 Author: Site Editor Publish Time: 2023-03-17 Origin: Site

HEAD Waterjet, the solution for splicing and cutting conveyor belts and timing belts

Customer Case -- HEAD Waterjet, the solution for splicing and cutting conveyor belts and timing belts

Company name: a transmission equipment manufacturer in Turkey

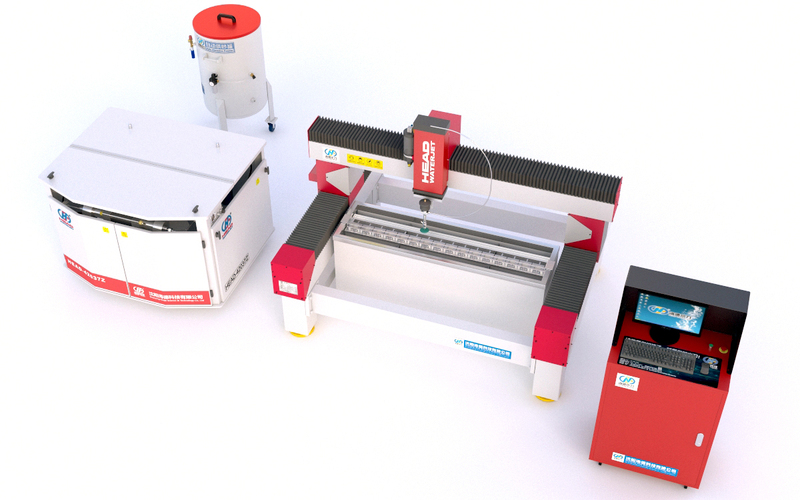

Waterjet model:HEAD1010BA-3A/HEAD42037Z

HEAD1010BA-3A/HEAD42037Z

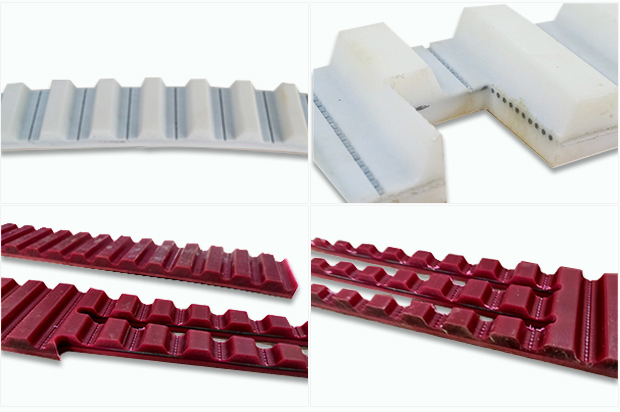

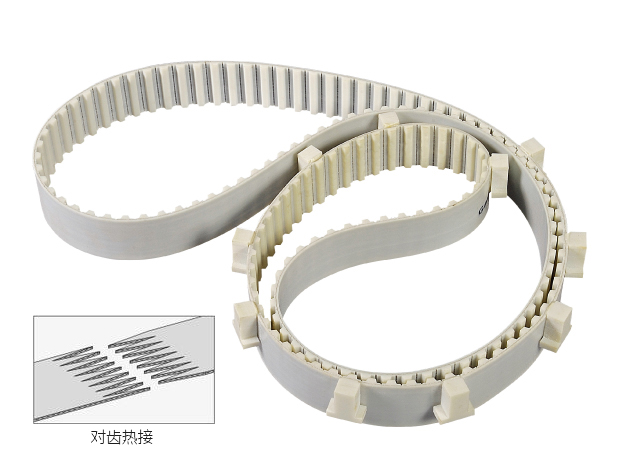

As we all know, one of the characteristics of high-pressure water jet cutting is that there is no selectivity in cutting materials, in addition to stone, metal, glass and other conventional materials can also achieve the cutting of composite materials and laminated materials, fast cutting speed, smooth cutting surface without burrs. This feature is applied in the conveyor belt, synchronous belt processing industry, conveyor belts, synchronous belts are mostly polyurethane materials and iron core or fabric calendering, in the process of use need to be spliced according to the different lengths, the splice of the cut is mostly round holes or other shaped, the industry's original solution for laser cutting, manual processing or knife die processing, such processing problems for the cutting surface burr quality can not meet the requirements, the need for secondary processing.

With the mission of solving all cutting problems for customers, HEAD Waterjet technical team uses different types of conveyor belts and synchronous belts for different speeds and different shapes of trial cutting, and the quality of the cut surface is good, with no puckering of polyurethane and internal core or fabric, which can meet customer quality standards.

This cutting solution has been approved by domestic and foreign customers now, and the water cutting machine has been exported to Turkey, Korea and other countries, if you have the same cutting needs, welcome to contact us for consultation.