- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HEAD0303BA

HEAD

| Availability: | |

|---|---|

Product Description

Desktop Waterjet Cutting Machine

Maximize precision and efficiency with our cutting-edge Desktop Waterjet Cutting Machine, designed for high-performance cutting in compact spaces.

Precision Engineering: Achieve cutting accuracy of ±0.1 mm and repeat positioning accuracy of ±0.05 mm, ensuring consistent and reliable results for even the most intricate projects.

Compact & Space-Efficient: With a compact footprint of 1300 x 1300 x 1650 mm, it fits seamlessly into labs, workshops, or research environments with limited space while maintaining robust performance.

High Pressure, High Performance: Operates at a maximum pressure of 200 MPa, delivering powerful cutting force for a wide range of materials, including metals, plastics, and composites.

Fast and Efficient: Achieve high-speed cutting with a max idle speed of 3000 mm/min, optimizing productivity without compromising on precision.

Safe & Quiet Operation: The integrated one-piece protective shield effectively reduces cutting noise and minimizes water vapor escape, ensuring a quieter and safer work environment.

Energy Efficient: With a total power consumption of just 4.5 kW, it delivers superior performance while keeping operational costs low.

Reliable Performance: Designed for industrial-grade reliability, it operates with air pressure requirements of ≥ 0.6 MPa and water pressure requirements of ≥ 0.4 MPa, making it ideal for long-term, continuous operation.

Versatile Applications: Capable of cutting a wide variety of materials with a maximum cutting travel of 300 mm x 300 mm, making it suitable for diverse industries such as aerospace, automotive, and research.

Direct Drive Pumps

Detailed image

Technical Parameters

| Operating Temperature Range | 20-25°C |

| Dimensions (L x W x H) | 1300 x 1300 x 1650 mm |

| Max Load on Cutting Platform | 60 kg |

| Max Pressure | 200 MPa |

| Cutting Travel | 300 mm x 300 mm |

| Max Idle Speed | 3000 mm/min |

| Air Pressure Requirement | ≥ 0.6 MPa |

| Water Pressure Requirement | ≥ 0.4 MPa |

| Total Power Consumption | 4.5 kW |

| Repeat Positioning Accuracy | ± 0.05 mm |

| Cutting Accuracy | ± 0.1 mm |

| Max Flow Rate | 1 L/min |

Dimensions: 1300x1300x1650mm, compact size and lightweight (~500KG/m²), making it easy to move and saving valuable workspace.

Features a one-piece guard design that significantly reduces cutting noise and prevents water vapor leakage, ensuring both a safer and more comfortable working environment.

Pressure Loss Protection: Automatic pressure loss alarm and shutdown to prevent damage due to abnormal pressure drops.

Water Shortage Protection: High-pressure pump has a water shortage alarm, preventing damage caused by insufficient water supply.

Pressure Relief Function: The high-pressure pump features a pressure relief valve that activates after cutting stops, preventing damage from sudden stops and restarts.

Cooling System: Optional small-scale water-cooling machine for separate circulation cooling, enhancing the high-pressure pump's temperature control and cooling performance.

Material Platform: Standard galvanized material for the feeding platform, with the option to upgrade to stainless steel for better durability and efficiency.

Equipped with mechanical gauges to monitor water pressure and air pressure in real-time for better operational control.

Digital pressure display for real-time monitoring of the high-pressure pump’s water output pressure, ensuring precise cutting.

Features emergency stop buttons and start/stop buttons for immediate shutdown in critical situations.

Network and USB interfaces for seamless computer connectivity and external power supply connections.

Utilizes high-precision ball screws and guide rails, ensuring superior transmission accuracy and durability for precise and consistent cutting performance.

Sealed Fabric Covers: The XY-axis drive structure uses integrated sealed fabric covers, effectively preventing water vapor and splashing, ensuring a clean and organized workspace.

Protective Guard: The overall design includes a protective guard that reduces cutting noise, contributing to a healthier working environment.

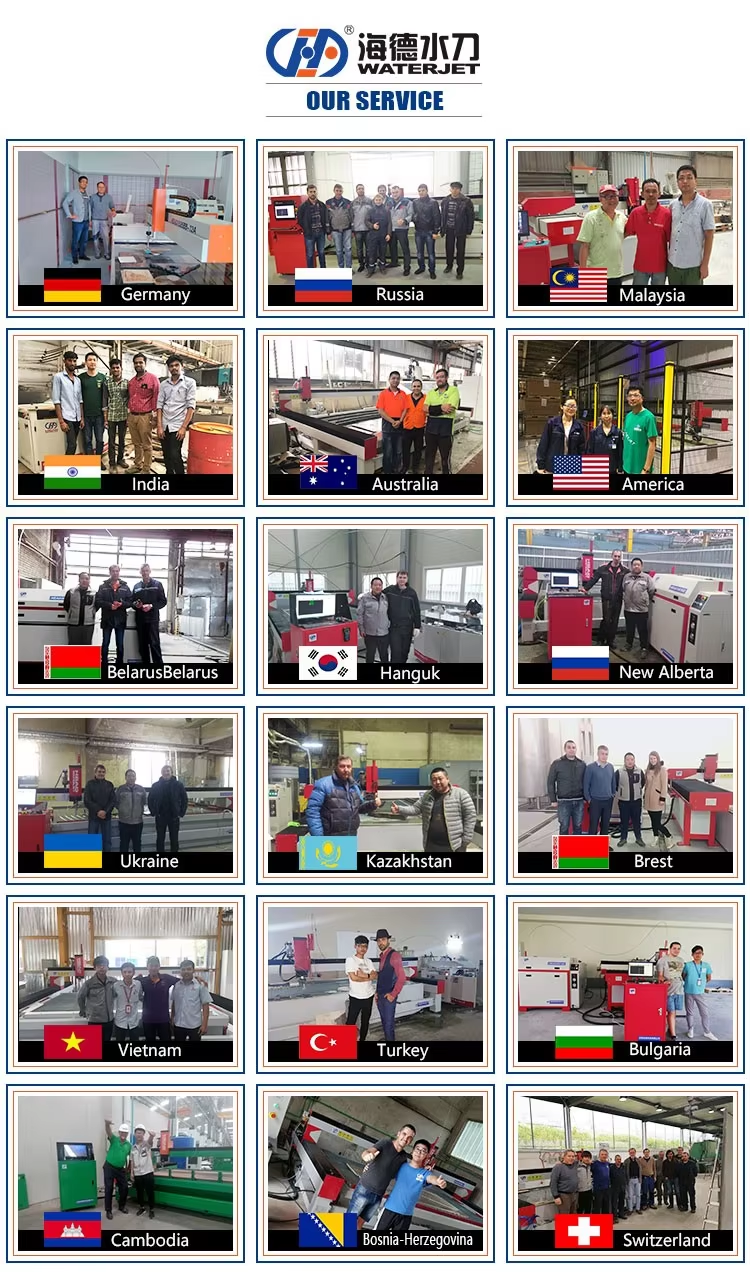

Our Service

After-Sales Service Excellence for Waterjet Cutting Machines

At HEAD Waterjet, we understand that reliable after-sales service is as crucial as the performance of our cutting machines. We are committed to offering unparalleled support to ensure your operations run smoothly and efficiently.

Key Benefits of Our After-Sales Service:

24/7 Support: Our dedicated service team is available around the clock, ensuring quick resolutions to any issues you may encounter, minimizing downtime and maximizing productivity.

Comprehensive Training: We provide detailed training to your team on machine operation, maintenance, and troubleshooting, empowering you to get the most out of your equipment.

Cost-Effective Maintenance: We offer affordable, transparent pricing for all after-sales services, helping you control operational costs without compromising on quality.

Global Reach: With an extensive network of service centers and technicians, we guarantee fast and efficient support no matter where you are.

Genuine Parts and Upgrades: We use only genuine parts to ensure the long-term reliability and performance of your equipment. Additionally, we offer periodic upgrades to keep your machine running at peak efficiency.

Choose HEAD Waterjet for reliable performance and peace of mind—our after-sales service is designed to keep your operations running seamlessly.

Quality Inspection for HEAD Waterjet Machines

At HEAD Waterjet, quality is at the core of everything we do. Our commitment to delivering high-performance cutting machines means that every system undergoes rigorous quality control and testing before it reaches you.