- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 3 Author: Site Editor Publish Time: 2021-04-26 Origin: Site

Inner hole first,then outer frame

When cutting with waterjet, you must consider cutting the inner hole first and then the outer frame. Otherwise, when the outer frame and the mother sheet are cut and then the inner hole is cut, it will easily cause horizontal movement or shake up and down due to water tossing, which will affect the cutting accuracy.

Lead-in and lead-out

Before cutting, a hole is punched in the material, and then the cutting starts from the hole. Usually, it takes a certain amount of time to punch holes, and dots larger than normal cutting will appear in the punch holes.

Lead-in and lead-out

If there is a smooth requirement for the cut edge, you need to add lead-in and lead-out lines when programming.

Pay attention to the direction of the lead-in and lead-out lines.

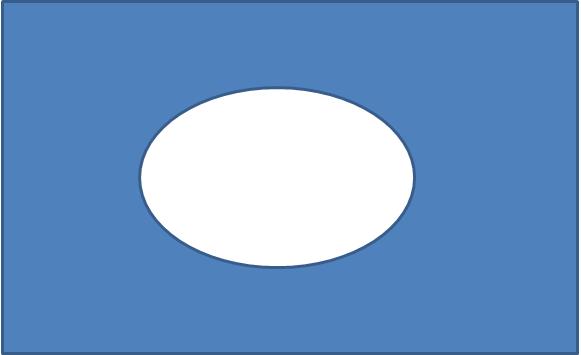

Tool compensation

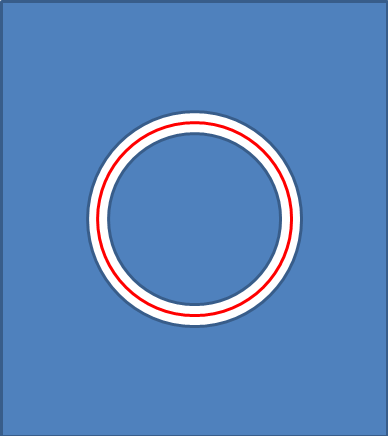

Water cutting, like other cutting methods, will produce knife seams. If you don't consider this, the cut parts will have the error of the knife seamCut a 100mm diameter hole with water cutting.White knives are sewn. The width is 1mm.Red is the cutting path that the knife core passes.The diameter is 100mm.Question:

1. What is the finished size of this inner hole?

2. What is the diameter of the finished wafer?

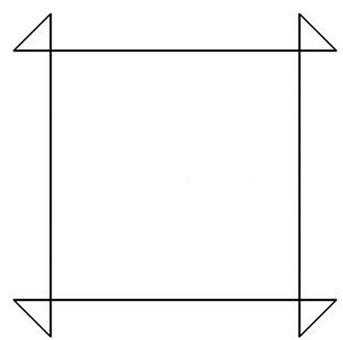

Deceleration at inflection point

Due to the jet lag, there will be a small corner below the four corners of the cut object that is not cut, so that the workpiece cannot be taken off.

The first process:

Like the picture

we called it well cutting method.This method can avoid the situation that the corners are cut continuously to a certain extent.

limitation:

The method can and avoid the impact of jet lag. However, graphics that only target the outer contours are not suitable for all graphics. Moreover, this method is invalid for the retract point.